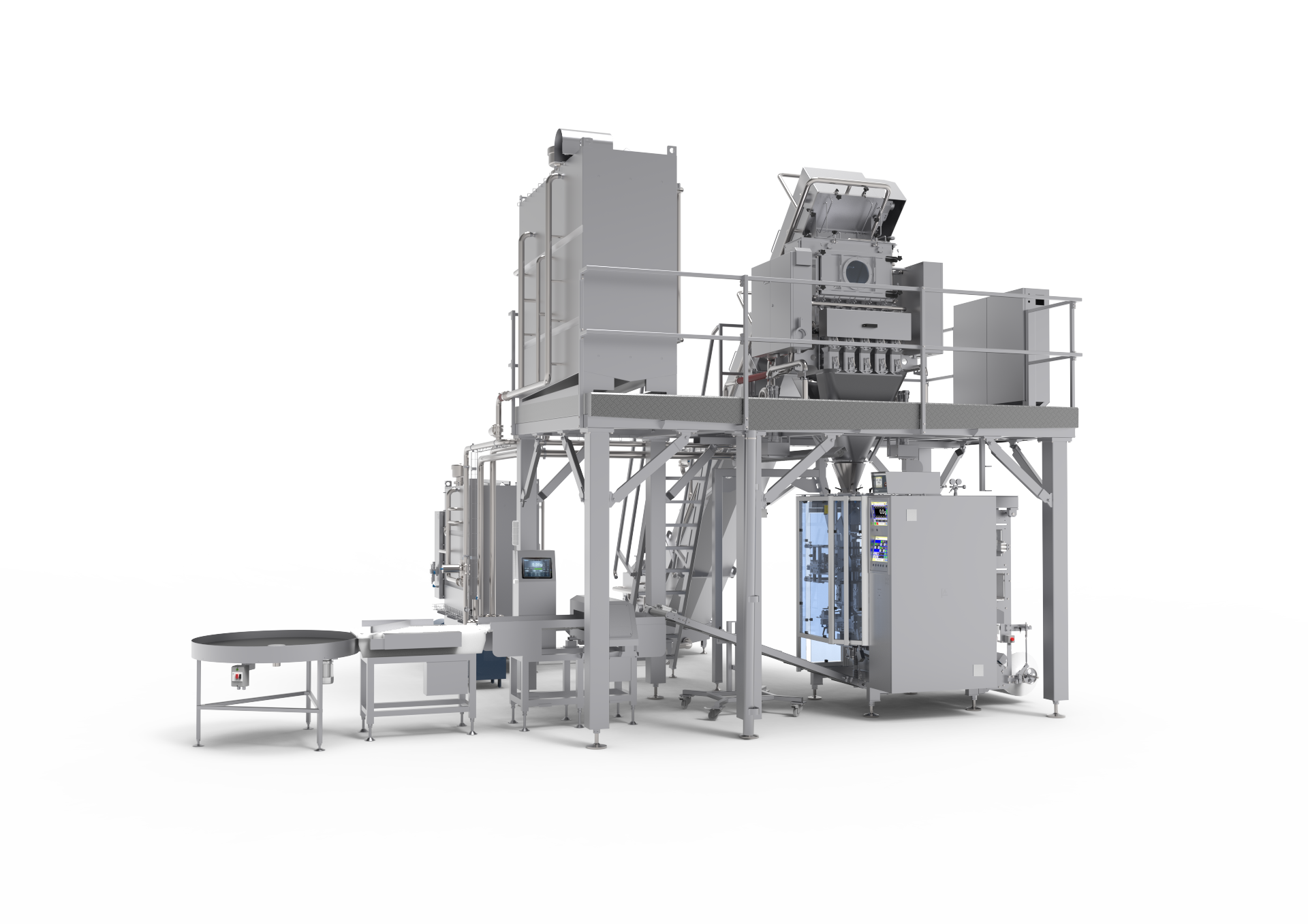

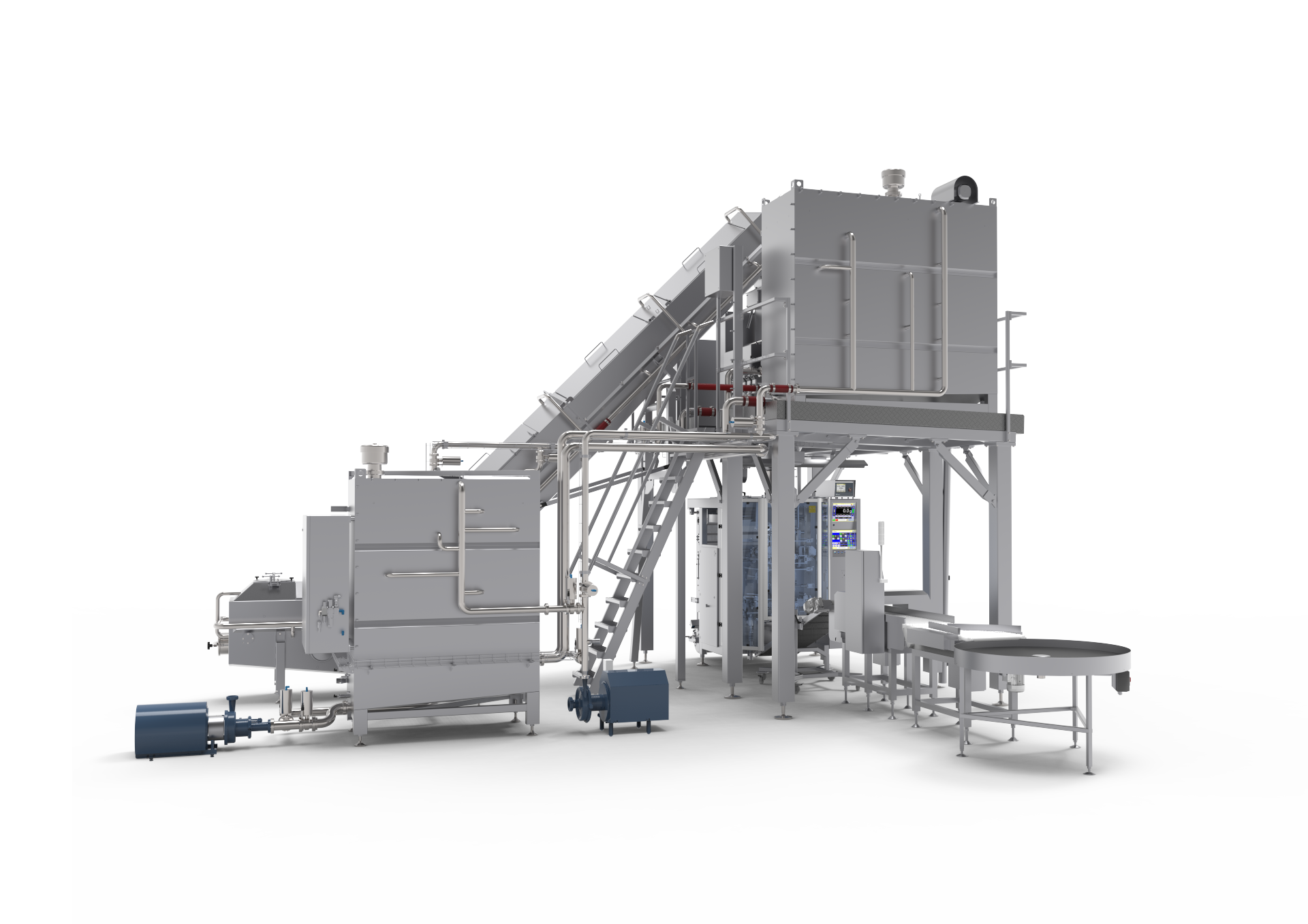

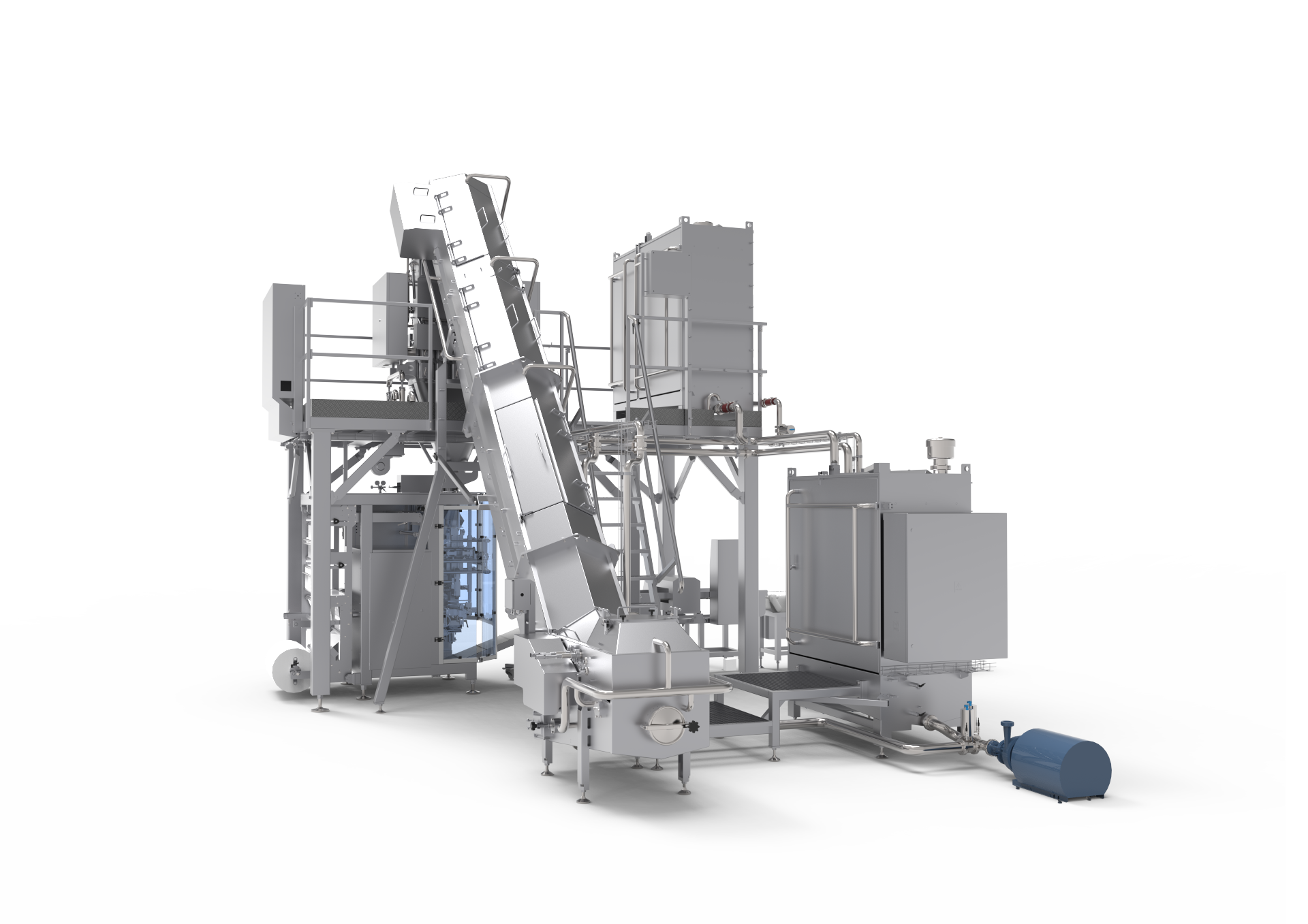

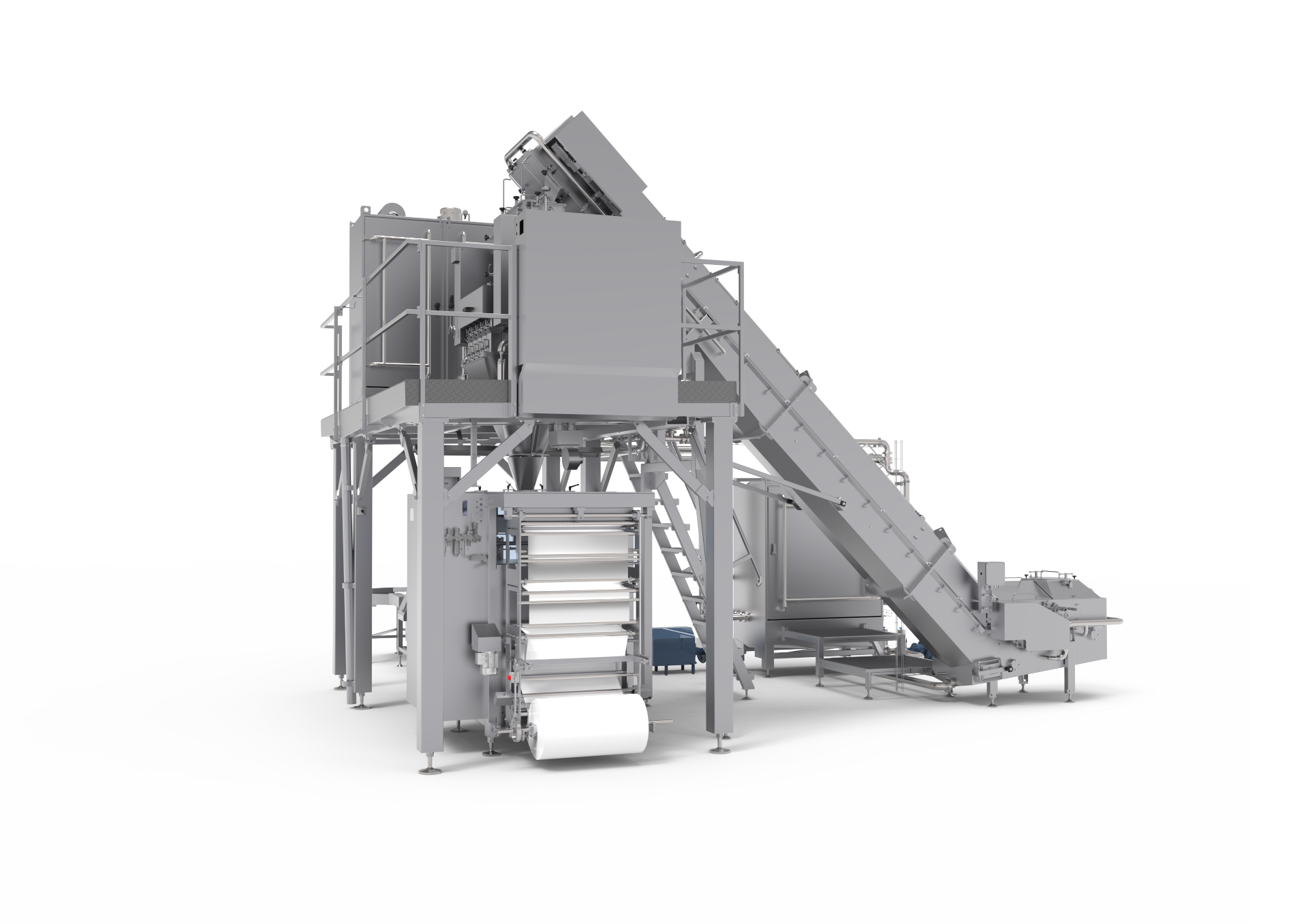

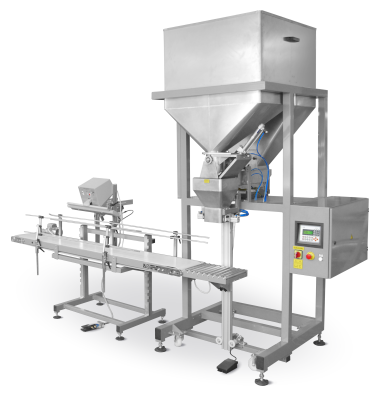

Semi-automatic dosing machines for dusty, badly loose and powdery products ground coffee, flour, powdered sugar, pudding powder, gypsum, washing powders, color powder, cement and mortar mixtures, ...

Semi-automatic dosing machines for dusty, badly loose and powdery products ground coffee, flour, powdered sugar, pudding powder, gypsum, washing powders, color powder, cement and mortar mixtures, ... Semi-automatic dosing machines is designed for packaging into bags, boxes or other containers.

Variability of manual dosing devices

Technical parameters

| Machine type | PES6 | PES10 | AV2/1r | KL1r | MD2r |

| Output* (doses/min.) | to 10 | to 10 | to 30 | to 30 | to 30 |

| Weighing range | 5 - 50 kg | 5 - 30 kg | 6 - 7000 g | ||

| Dose volume of one cup (ml) | 85 - 1840 | 8 - 950 | |||

| Volume of weigh hopper (l) | 7,0 | ||||

| Dose accuracy | according to standard "e" | according to standard "e" | according to standard "e" | according to standard "e" | according to standard "e" |

| Hopper volume (l) | 500 | 90 | 30 | 30 | 30 |

| Power supply | 3 x 230 V/400 V - 50 Hz | 3 x 230 V/400 V - 50 Hz | 230 V - 50 Hz | 3 x 230 V/400 V - 50 Hz | 3 x 230 V/400 V - 50 Hz |

| Air consumption at 0,6 MPa (l / dose) | 0,1 | 0,35 | 0,1 | ||

| Noise (dB) | 75 | 78 | 75 | 60 | 60 |

| Machine weight (kg) | 300 | 450 | 250 | 100 | 100 |

| Dimensions L x H x W (mm) | 2750x3260x1854 | 2410x2130x3220 | 1885x860x1960 | 2030x1500x1025 | 1450x1590x890 |

*Output depends on dose size, kind of goods, required accuracy and skill of the operator.

Types of packaging

| Machine type | PES6 | PES10 | AV2/1r | KL1r | MD2r |

| bags | ● | ● | ● | ● | ● |

| sacks | ● | ● | ● | ● | ● |

| boxes | ● | ● | ● | ● | ● |

| doses | ● | ● | ● | ● | ● |

| jars | ● | ● | ● | ● | ● |

Machine description

| Machine type | PES6 | PES10 | AV2/1r | KL1r | MD2r |

| areas which are in contact with the goods are made of stainless steel | ● | ● | ● | ● | ● |

| all parts of the machine are protected health harmless surface treatment | ● | ● | ● | ● | ● |

| tensometric weighing unit | ● | ● | ● | ||

| one vibrating chute | ● | ||||

| two vibrating chutes in one flow | ● | ||||

| closing of end of vibratory chute | ● | ● | |||

| conveyor with hopper | ● | ||||

| foot pedal or two-handed starting | ● | ● | ● | ● | ● |

Accessories

| Machine type | PES6 | PES10 | AV2/1r | KL1r | MD2r |

| roll conveyor | ● | ● | ● | ● | ● |

| discharge conveyor OD5 | ● | ● | ● | ● | ● |

| bag closing unit holder | ● | ● | |||

| bag closing unit | ● | ● | |||

| sealer | ● | ● | ● | ● | ● |

| automatic bag closing | ● | ● | ● | ||

| feeding conveyor VD1 | ● | ● | ● | ● | ● |

| feeding scew conveyor VD5 | ● | ● | ● |

Advantages

| Machine type | PES6 | PES10 | AV2/1r | KL1r | MD2r |

| automatic checking of product level in hopper | ● | ● | ● | ● | ● |

| easy and quick exchange of measuring cup | ● | ● | |||

| possibility of emptying of one or more doses at once | ● | ● | |||

| easy to use | ● | ● | ● | ● | ● |

| easy cleaning | ● | ● | ● | ● | |

| display of the actual weight in grams | ● | ● | ● | ||

| automatic control of goods level in vibrating chute | ● | ● | ● | ||

| automatic state diagnostics | ● | ● | ● | ● | |

| automatic tare | ● | ● | ● | ||

| seeting of all functions from control panel | ● | ● | ● | ● | ● |

| seeting of all functions from portable control panel | ● | ||||

| 30 memories for various kinds of goods (name 8 symbols) | ● | ● | ● | ||

| world´s languages foroperating English, German, Russian and Czech | ● | ● | ● | ||

| two weighing modes | ● | ||||

| counting of average dose from previous 20 doses | ● | ||||

| possibility connection to PC | ● |

Modification

| Machine type | PES6 | PES10 | AV2/1r | KL1r | MD2r |

| possibility to connect conveyor for discharging of full sacks | ● | ● | |||

| covering | ● | ● | ● | ● | ● |

| automatic attachment of package | ● | ● | ● | ● | ● |

| for breakable and brash goods (durable pastry etc.) | ● | ||||

| for frozen goods contra freeze (vegetable, chips) | ● | ● | ● | ||

| separation of abrasion packaged goods | ● |