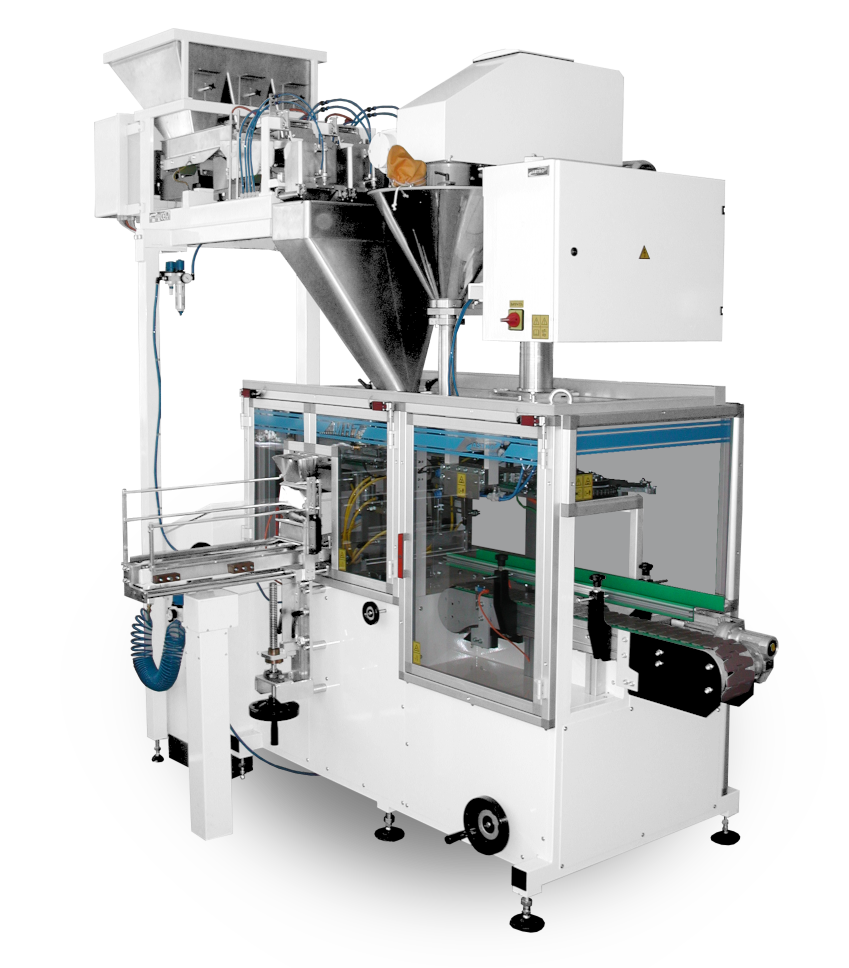

Machine PL1 and MH7 series are designed for packing products into pre-made bags.

Unlimited Variability

Technical parameters

| machine type | PL1bb | PL1cb | MH7 |

| dose volume (l) | up to 1,5 | up to 6,0 | up to 1,5 |

| output* (bags/min.) | up to 20 | up to 15 | up to 30 |

| bags height (mm) | 150 - 300 | 240 - 440 | 120 - 300 |

| bag width (mm) | 80 - 130 | 120 - 220 | 80 - 160 |

| bag thickness (mm) | 30 - 70 | 50 - 120 | - |

| power supply | 3 x 230 V/400 V - 50 Hz | 3 x 230 V/400 V - 50 Hz | 3 x 230 V/400 V - 50 Hz |

| power (kW) | 2,0 | 2,0 | 5,5 |

| air pressure (MPa) | 0,6 - 0,8 | 0,6 - 0,8 | 0,6 - 0,8 |

| air consumption per 1 bag at 0,6 MPa (l) | 1,0 | 1,0 | 0,2 |

| noise (dB) | up to 75 | up to 75 | up to 75 |

| machine weight (kg) | 950 | 950 | 950 |

| machine dimensions L x W x H (mm) | 6240 x 1160 x 1790 | 6240 x 1160 x 1790 | 2600 x 1600 x 1550 |

* Packing output depends on bag size, kind of goods and output of used filler

Bags types

| machine type | PL1bb | PL1cb | MH7 |

| pillow bag | ● | ||

| gusset bag | ● | ● | |

| doypack | ● |

Packaged products

| machine type | PL1bb | PL1cb | MH7 |

| loose products | ● | ● | ● |

| granulates | ● | ● | ● |

| liquids | ● |

Machine description

| machine type | PL1bb | PL1cb | MH7 |

| fold of the top bag and then suturing, conglutination, welded or sealed with a label | ● | ● | |

| adjustable equipment for welding of top weld | ● | ||

| display of minute capacity | ● | ● | ● |

| pneumatics Festo | ● | ● | ● |

| electronic resistant to short circuit, reversing of polarity and overloading | ● | ● | ● |

| lifetime lubricating charges | ● | ● | ● |

| electric cover IP 44 | ● | ● | ● |

| automatic state diagnostics | ● | ● | ● |

| all setting of functions is from control panel | ● | ● | ● |

| areas which are in contact with the goods are made of stainless steel | ● | ● | ● |

| all parts of the machine are protected health harmless surface treatment | ● | ● | ● |

Advantages

| machine type | PL1bb | PL1cb | MH7 |

| easy setting of functions and parameters on control panel | ● | ● | ● |

| automatic check of essential parameters and error reports | ● | ● | ● |

| 100 presets for saving of parameters for various film types and packaging methods | ● | ● | ● |

| fast and easy setup package dimensions | ● | ● | ● |

| operating language according to your choice - 4 standard languages | ● | ● | ● |

| stop the machine after the specified number of bags | ● | ● | ● |

| display of bags quantity to the abortion of operation | ● | ● | ● |

| display of total cycles quantity | ● | ● | ● |

| simplicity of design of the drive | ● | ● | ● |

| possibility of connection to PC, printer, ethernet | ● | ● | ● |

| program service via modem | ● | ● | ● |

Accessories

| machine type | PL1bb | PL1cb | MH7 |

| dosing weighers | ● | ● | ● |

| flap or friction volumetric filler | ● | ● | ● |

| auger filler | ● | ● | ● |

| liquid filler | ● | ||

| screw conveyor | ● | ● | ● |

| belt conveyor | ● | ● | ● |

| discharge conveyor | ● | ● | ● |

| recommended compressor 100 l / min. | ● | ● | ● |

| date printing by inkjet printer | ● | ● | ● |

Modifications

| machine type | PL1bb | PL1cb | MH7 |

| auger and volumetric fillers combination | ● | ||

| dosing weighers and auger filler combination | ● |