Packaging machines are designed for packaging goods into bags that the machine creates from a roll of foil.

Packaging machine designed for packaging goods into block bags ( brickpack). The compact shape of the bag reduces transport and storage costs. The attractive appearance of the bag is more interesting on the shelves

Packaging machines for packing dusty and liquid products into water-soluble foil. Suibtable for products such as washing powders and gels, dishwasher gels, agricultural chemicals, etc.

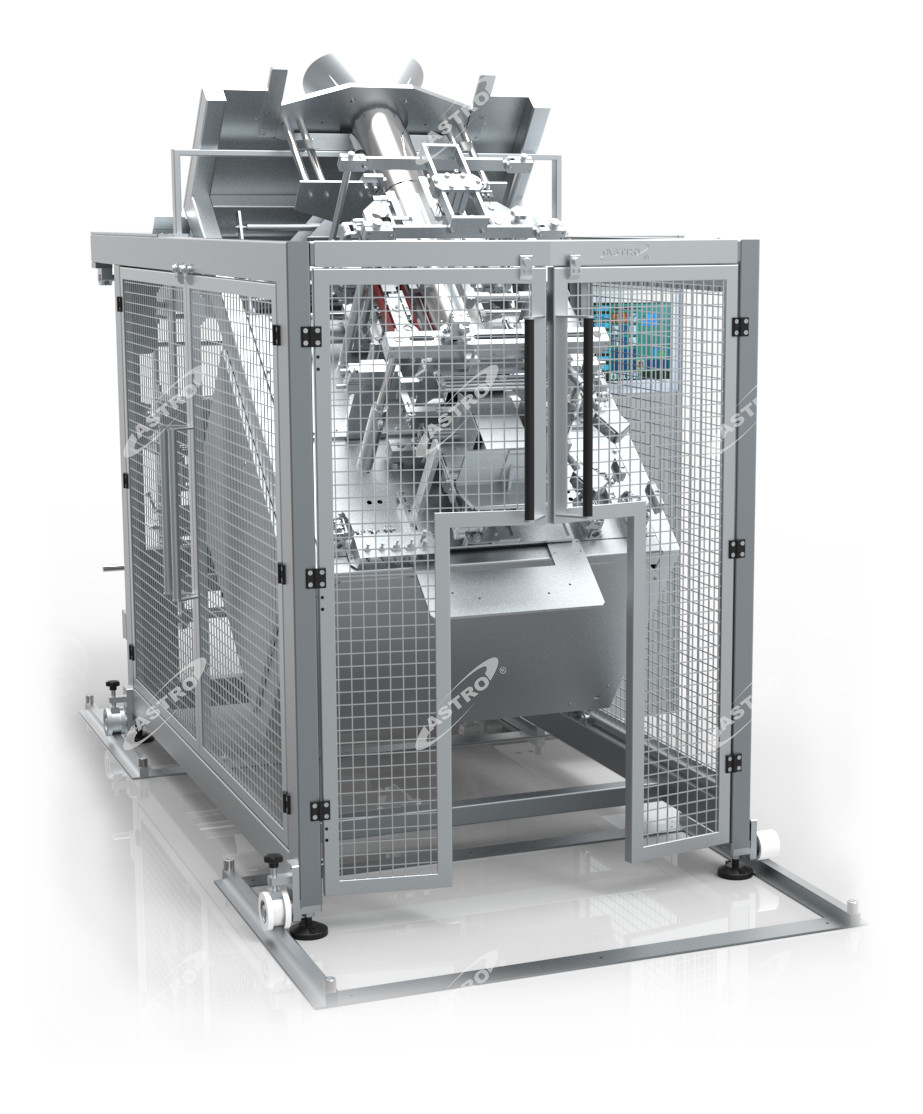

The machine presses the goods before packaging. Suitable for products such as straw, hay, wood shavings and sawdust, poypropylene staple ( concrete fibers), etc.

The optional tilt of the tube enables gentle packaging of goods. Suitable for fragile products ( shortcrust pastry, biscuits, etc.) and heavy products (vegetables, potatoes, onions, etc.).

The machine design allows easy cleaning. The machines are designed for freezers, dairies, etc. The machines are suitable for packaging liquids, meat products, dairy products, etc.